-

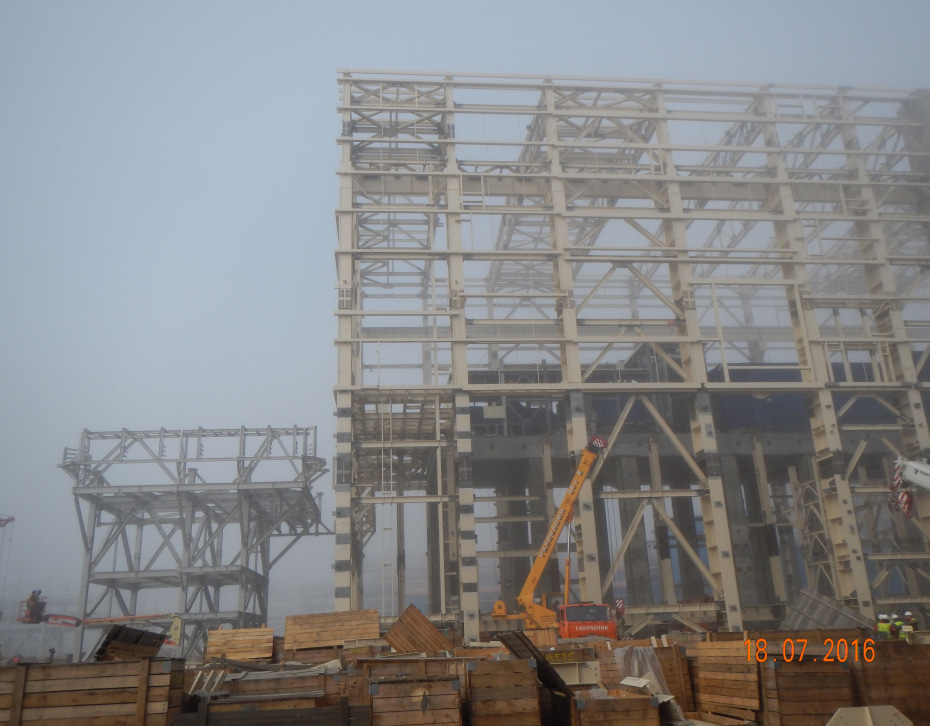

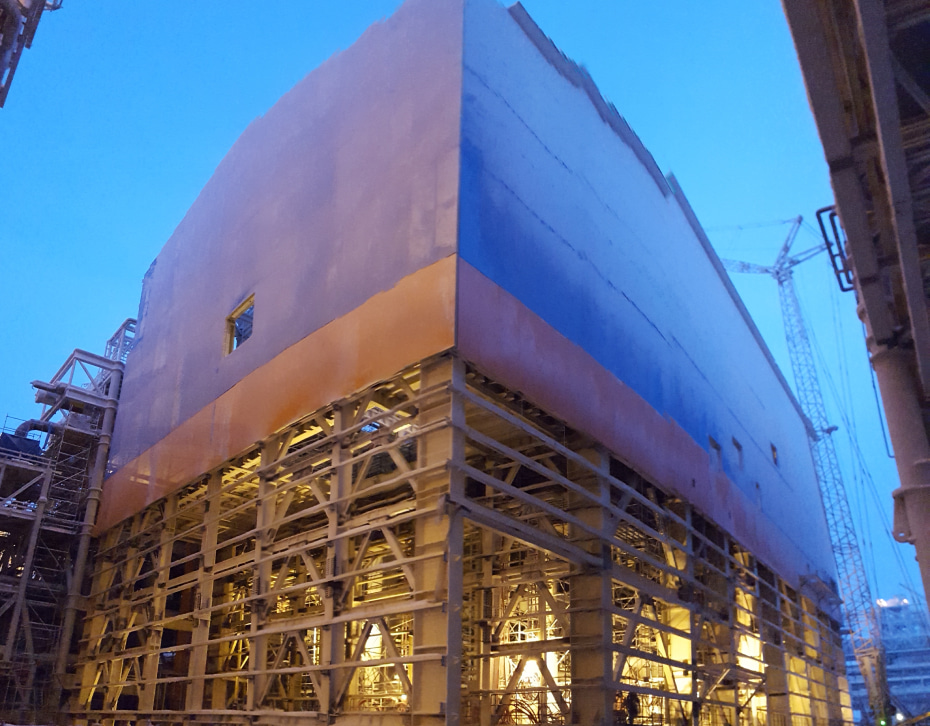

2015 - 2017 Yamal LNG natural gas liquefaction plant.

Application of protective coating to surfaces in the setting of the metal structure manufacturing plant.

4 projects

Tasks

- 2015, 2016, 2017 Development of design documentation and delivery of a set of works regarding the application of fireproof coating to metal structures of the Yamal LNG buildings and facilities in the setting of the CJSC KrasPTM metal structure manufacturing plant, Krasnoyarsk, Krasnoyarsk Territory.

- 2016, 2018 Development of design documentation and delivery of a set of works regarding the application of fireproof coating to metal structures of the Yamal LNG buildings and facilities in the setting of the ZZMK LLC metal structure manufacturing plant, Zlatoust, Chelyabinsk Oblast.

- 2016 - 2017 Development of design documentation and delivery of a set of works regarding the application of fireproof coating to metal structures of the Yamal LNG buildings and facilities in the setting of the Ak Bars Metall LLC metal structure manufacturing plant, Nabereznye Chelny, Tatarstan Republic.

- 2016 - Development of design documentation and delivery of a set of works concerning the application of fireproof coating to metal structures of buildings and facilities of Input Gas Treatment Facilities, Sabetta Village, Yamalo-Nenets Autonomous Okrug.

The fireproofing design documentation was developed with the consideration of technical particulars and requirements for application of protective coating in the setting of the metal structure manufacturing plant.

Each project entailed graphic detailed design of all building frame elements at the Tekla Structures software complex.

over 100,000 sq m

Total area of completed works for the Yamal LNG project

FEATURES

- Works were carried out at a few facilities simultaneously;

- All the fireproofing was completed for the case of hydrocarbon fire, with the thickness of the dry film standing at 13,000 μm (2 layers). The coating process involved the use of equipment with separate feeding of pre-heated components;

- The coating technology in the setting of the metal structure manufacturing plant provided the right climatic conditions, excluded the risks of noncompliance and complete construction works regardless of the season.

- The warranty period of delivered works is 10 years.